Industrial usage of Reverse Engineering

Industrial usage of reverse engineering in various fields

Reverse Engineering is being applied to generate CAD files. Specialized software is used with CMM and a touch probe in two demonstration experiments. Advantages of the technique include immediate feedback, data reduction, direct generation of geometry and higher precision of the final product.

Reverse Engineering in manufacturing and engineering is used to find out how equipment or products are made and work.

Reverse Engineering in manufacturing and engineering is used for a wide variety of reasons. By taking apart engineering equipment or a manufactured product and discovering the materials it is made from and how it works, we can help a business determine and improve production processes, enhance product effectiveness, and protect patents.

The process is also used to discover how a ‘legacy’ (i.e very old) component or product operates and is necessary when the original technical drawings and material information are no longer available or the original manufacturer is no longer in business.

Reverse Engineering requires multidisciplinary expertise and experience when deconstructing an item.

Examples of Reverse Engineering in Industrial usage

Following are some of the examples presented to us by experts in the industry – Reverse Engineering Service (RES)

• CAD data for mould production

Classic clay modeling is still widely used during the design process for creating shapes and models.

Reverse engineering here, helps in two ways:

- 3D Scan of clay model

- Reverse engineering and free form modelling of the 3D Scan – STL file (Catia V5/V6)

Example: Mold-milling of a new Santa Claus, to be made of chocolate

• CAD data for construction of injection molds

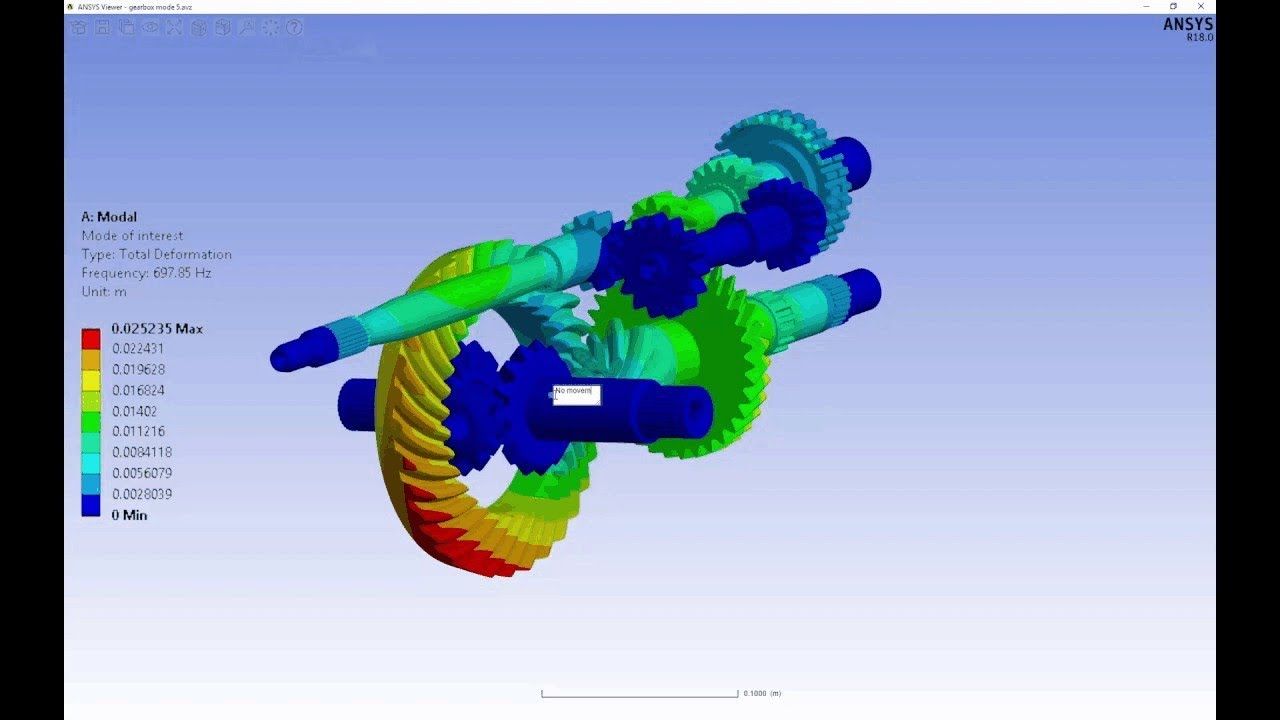

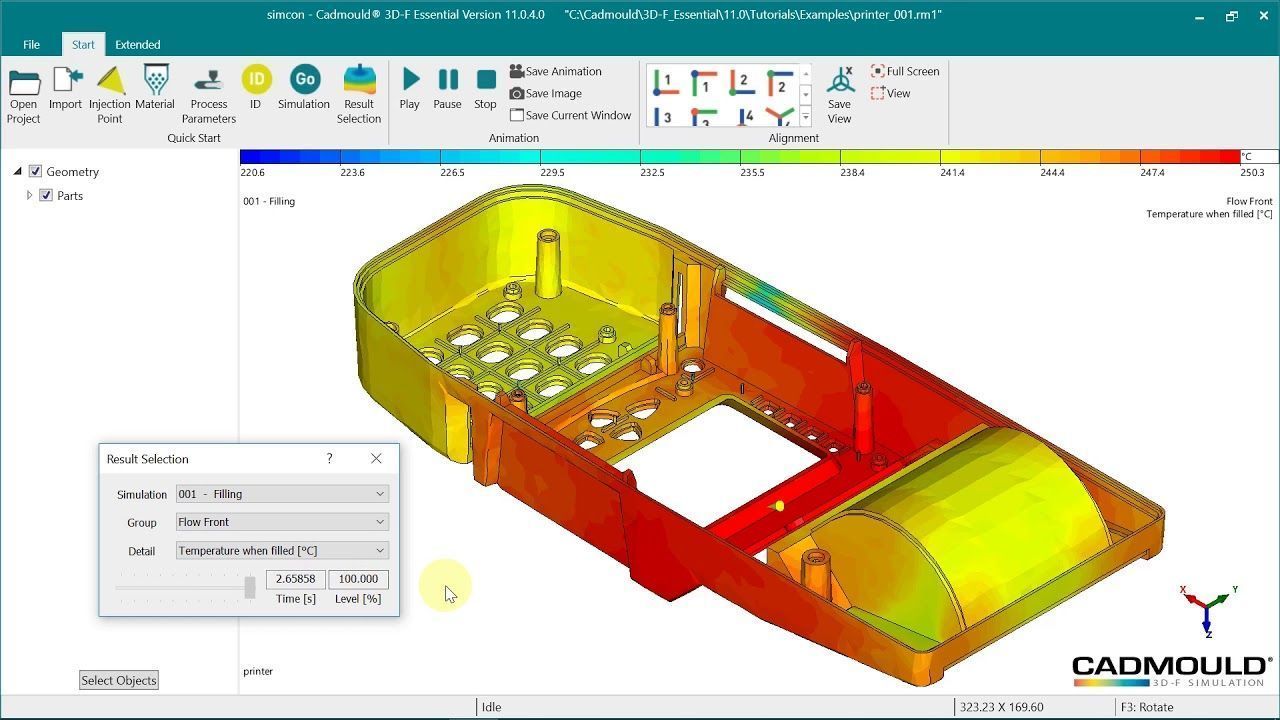

Cadmold software simulates material flow during injection moulding processes. Simulation is done on the original CAD construction file and the result of this simulation is a pointcloud with variations on the surface. This pointcloud represents the expected result of the moulding process.

Reverse Engineering Service (RES) remodels this pointcloud back to CAD data. Based on this new CAD file, the mould design can be further optimized in areas where tolerances are outside of the requested range.

Here, Reverse Engineering applies in these ways:

- Moldflow simulation of hot plastics with Cadmold software

- Reverse engineering with free form modelling and remodeling of parametric geometries (various software)

Example: Injection molding of plastic parts for use in hospital ventilators

Comments

Post a Comment

Thank you for your message! We value your feedback!